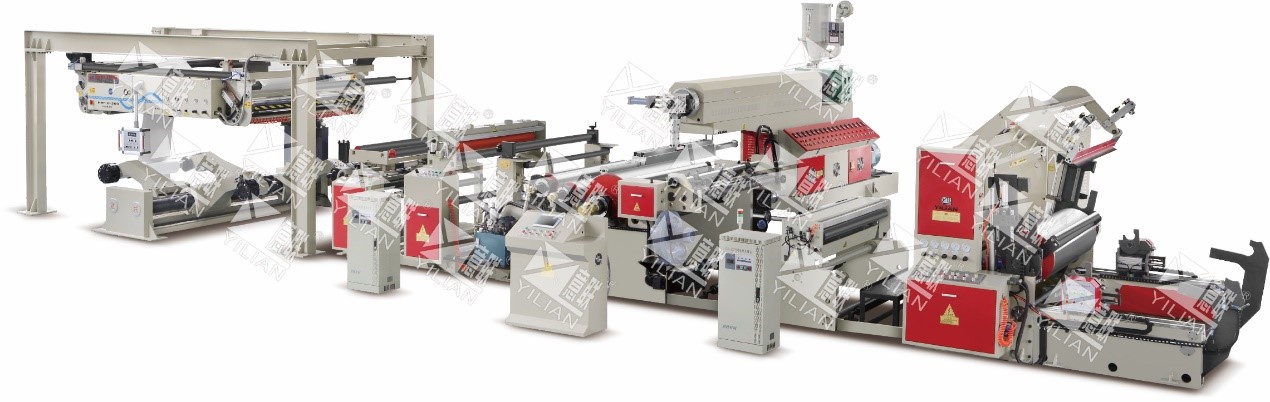

WSFM1300C Akpaaka Akwụkwọ PE Extrusion mkpuchi igwe

| Suit laminating resin | LDPE, PP, wdg |

| Suit isi ihe | akwụkwọ (80-400g/m²) |

| Oke n'ibu ọsọ | 300m / min (arụ ọrụ ọsọ na-adabere na mkpuchi ọkpụrụkpụ, obosara) |

| Obosara mkpuchi | 600-1200, obosara akwụkwọ ntuziaka: 1300mm |

| mkpuchi mkpuchi | 0.008-0.05mm (otu ịghasa) |

| Njehie ọkpụrụkpụ mkpuchi mkpuchi | ≤±5% |

| Oke ntọala esemokwu akpaaka | 3-100kg zuru oke |

| Ọnụ ọgụgụ extruder kacha | 250 n'arọ / h |

| Mgbakwụnye rola jụrụ oyi | ∅800×1300 |

| Ịghasa dayameta | ∅110mm ruru 35: 1 |

| Dayameta iwepụ ikuku kacha | ∅1600mm |

| Dayameta nlaghachi azụ | ∅1600mm |

| Wepu isi akwụkwọ dia: 3 ″ 6 ″ yana dayameta isi akwụkwọ laghachi azụ: 3″ 6″ | |

| Extruder na-eji 45kw | |

| Mkpokọta ike | ihe dịka 200 kw |

| Ibu igwe | ihe dị ka 39000kg |

| Akụkụ dị n'èzí | 16110 mm × 10500 mm × 3800 mm |

| Igwe ahụ agba | Agba ntụ na uhie |

1. Unwind akụkụ (na PLC, servo unwinding)

1.1 Igwe anaghị agba nchara

Ihe owuwu: ogwe osisi hydraulic na-enweghị ikuku na-ekpugharị

Usoro BA usoro splicer bụ akụkụ dị mkpa nke ahịrị lamination ma tinye ya n'elu akwụkwọ mpịakọta n'okpuru ihe owuwu akwa mmiri. Ọ na-enye ohere ịga n'ihu na-agba ọsọ nke akwụkwọ mpịakọta dị na mpịakọta akwụkwọ na-esote na-enweghị nkwụsị nke mmepụta.

N'ime okpokolo agba n'akụkụ splicer bụ isi splicing 2 mbugharị na ngalaba nkwado etiti nke mbughari. N'elu ya bụ mpịakọta nip 2.

Akwụkwọ mpịakọta capstan, reverse idler roll na usoro ịgba egwu okpukpu abụọ na-etolite ngalaba mkpokọta akwụkwọ nke nwere ike ịkwakọba akwụkwọ ruru okpukpu anọ n'ogologo splicer.

A na-arụ ọrụ igwe ahụ site na panel panel na igwe

Ọsọ njikọ akwụkwọ Max.300m/min

a) mgbe ike akwụkwọ n'elu 0.45KG / mm, max. 300m/min;

b) mgbe ike akwụkwọ n'elu 0.4KG / mm, max. 250m/min;

c) mgbe ike akwụkwọ n'elu 0.35KG / mm, max. 150m/min;

obosara akwụkwọ

Oke. 1200mm

Min. 500mm

Ọsọ CE-300

Oke. 300m/min

data pneumatic

Tọọ nrụgide 6.5 mmanya

Min. mgbali 6 mmanya

Ụdị CE-300

Ike 3.2kVA, 380VAC/50Hz/20A

Voltaji njikwa 12VDC/24VDC

1.1.1 Independent haịdrọlik aro spindle mwekota ogwe aka ụdị abụọ-arụ ọrụ unwinding , na-enweghị ikuku aro , hydraulic loading , zọpụta ego nke loading n'ibu Ọdịdị. Akpaaka AB shaft auto reel ọzọ, obere ihe mkpofu.

1.1.2 Max. ogologo dia: 1600mm

1.1.3 Nchekwa esemokwu akpaaka: 3-70kg oke oke

1.1.4 ziri ezi esemokwu: ± 0.2kg

1.1.5 isi akwụkwọ: 3 "6"

1.1.6 Sistemụ njikwa nchekasị: ụdị ihe nchọta ihe mgbakasị ahụ site na nhụsianya nchọpụta nke potentiometer ziri ezi, njikwa etiti nke PLC mmemme.

1.1.7 Sistemụ njikwa mbanye: PIH cylinder braking, nzaghachi ntụgharị rotary ngwa ngwa, nrụgide ziri ezi na-achịkwa valvụ mechiri emechi akara aka, njikwa mmemme PLC

1.1.8 Ntọala esemokwu: Site na nrụgide ziri ezi na-achịkwa ntọala valvụ

1.2 ụdị ịchekwa akpaaka, ịcha ngwaọrụ

1.2.1 Nchekwa site na pneumatic moto buffer, hụ na esemokwu kwụsiri ike mgbe ị na-ewere akwụkwọ.

1.2.2 iche iche ịkpụ Ọdịdị

1.2.3 PLC akpaaka gbakọọ aro rotary ọsọ ọhụrụ, ma na-agba ọsọ na isi ahịrị ọsọ

1.2.4 Anata ihe pịa roller, cutter gbajiri ihe .nchebe njikwa mgbanwe, tọgharịa niile nwere ike mechaa na-akpaghị aka.

1.2.5 Roller mgbanwe tupu oti mkpu,: dayameta ọrụ mgbe iru 150mm., igwe ga-mkpu mkpu.

1.3 njikwa na-emezi: photoelectric putter rectifying control system (bst structure)

2. Corona (Yilian ahaziri)

Ike ọgwụgwọ Corona:20kw

3. Hydraulic lamination unit:

3.1 Atọ rollers laminating compound structure, back press roller, nwere ike ime ka ogige agba agba agba ọbụna, ụlọ ọrụ siri ike.

3.2 Mwepu nke silicon roba roller: ngwaahịa ngwaahịa dị mfe ilepụ anya na rola jụrụ oyi, hydraulic nwere ike pịa ya.

3.3 The curved mpịakọta film flattening Ọdịdị,: nwere ike ime ka film ngwa ngwa nkenye ọnọdụ

3.4 Compound ndepụta ihe mmezi ala nwere ike imeri film ihe ọkpụrụkpụ na-erughị eru na na adịghị ike

3.5 Igwe na-afụ ụfụ dị elu na-amịkọrọ ọnụ ngwa ngwa.

3.6 Ihe eji eme ihe ihe eji eme ihe

3.7 Compound roller bụ moto na-anya ya dabere

3.8 moto na-anya igwe na-agbakọ ọnụ bụ onye njikwa oge Japan na-achịkwa

Nkọwa:

(1) ihe mkpuchi: 800 × 1300mm 1pcs

(2) roba roba: 260 × 1300mm 1 pcs.

(3) pịa roller: 300 × 1300 mm 1pcs.

(4) cylinder mmanụ na-agbakọta:¢63 × 150 2pcs

(5) wepụ ihe mkpuchi: 130 × 1300 1pcs

(6) 11KWmotor (SHANGHAI) 1 set

(7) 11KW Frequency Ntụgharị (JAPAN YASKAWA)

(8) ntụgharị njikọ: (2.5"2 1.25"4)

4. Extruder (akpaaka elu ukpụhọde)

4.1 ịghasa dayameta:¢ 110, Max extruder banyere: 250kg / h (Japanese technology)

4.2 T-anwụ anwụ (Taiwan GMA)

4.2.1 Ebu obosara: 1400mm

4.2.2 Ebu dị irè obosara: 500-1200mm

4.2.3 Ebu egbugbere ọnụ ọdịiche: 0.8mm, mkpuchi ọkpụrụkpụ: 0.008-0.05mm

4.2.4 Mkpuchi ọkpụrụkpụ njehie:≤± 5%

4.2.5 Igwe ọkụ ọkụ eletrik n'ime kpo oku, kpo oku dị elu dị irè, okpomọkụ na-abawanye ngwa ngwa

4.2.6 Ọnụ ụzọ chiri anya kpamkpam, ndozi obosara ihe

4.3 Ngwa netwọk mgbanwe ngwa ngwa

4.4 N'ihu na azụ ije ije, nwere ike ibuli Trolley na-akpaghị aka, ebuli elu: 0-100mm

4.5 Mold 7 mpaghara okpomọkụ akara. Ịghasa gbọmgbọm 8 ngalaba okpomọkụ akara. njikọ 2 mpaghara okpomọkụ njikwa na-anabata nkeji kpo oku infrared.

4.6 Nnukwu ike igbe mbelata gia, eze siri ike (Guo tai guo mao)

4.7 Digital okpomọkụ njikwa akpaka okpomọkụ akara

Isi akụkụ:

(1) 45kw AC moto (SHANGHAI)

(2) Ihe ntụgharị ugboro 45KW (JAPAN YASKAWA)

(3) Digital okpomọkụ njikwa 18pcs

(4) 1.5KW moto ije

5.Pneumatic Round mma trimming ngwaọrụ

5.1 Trapezoidal ịghasa transverse mgbanwe ngwaọrụ, gbanwee ịcha obosara nke akwụkwọ

5.2 Onye na-egbutu nrụgide pneumatic

5.3 5.5kw elu mgbali onu absorb

6.Rewinding Unit: 3D arọ ọrụ Ọdịdị

6.1 Frame Ntugharị:

6.1.1 Esemokwu ụdị electric abụọ ọdụ rewinding igwe, elu-ọsọ akpaka ọnwụ na iburu okokụre ihe, akpaka ebutu.

6.1.2 Max. dayameta azụ azụ: 1600 mm

6.1.3 mpịakọta ọsọ: 1r / min

6.1.4 esemokwu: 3 - 70kg

6.1.5 ziri ezi: 0.2kg

6.1.6 isi akwụkwọ: 3 ″ 6 ″

6.1.7 Sistemụ njikwa ụjọ: Ogwe cylinder ahụ na-ese n'elu ụdị ihe nrụnye na-ese n'elu mmiri, a na-achọpụta esemokwu ahụ site na nkenke potentiometer, yana onye njikwa mmemme PLC na-achịkwa esemokwu ahụ. (Japan SMC obere esemokwu cylinder) 1 set

6.1.8 Sistemụ Njikwa Mbanye: 11KW moto mbanye, ntụgharị ntụgharị ọsọ ọsọ, Senlan AC inverter dual mechiri emechi njikwa, njikwa mmemme PLC nke etiti. 1 set

6.1.9 Ntọala nrụgide mgbe niile: Ntọala nrụgide nrụgide (Japan SMC)

6.1.10 Ntọala esemokwu taper: nke edobere na ihuenyo kọmputa, njikwa PLC, ntụgharị site na nha eletrik / ikuku (Japan SMC)

6.2 Ngwa nri na igbutu akpaaka

6.2.1 Splicing Nkwado Rollers bụ PLC na-achịkwa iji kwọọ moto ahụ iji jide ihe ahụ na igwe na-ehicha ihe.

6.2.2 Hydraulic Independent Cutter Mechanism

6.2.3 PLC akpaka ngụkọta oge nke ịtụ usoro, dochie nke olu na-mechara na a igodo

6.2.4 Ọrụ nke na-akwado Roller, ihe na-egbutu, Tọgharia, wdg. Emechara na-akpaghị aka

6.2.5 Nkọwapụta

(1) Roller esemokwu: ¢700x1300mm 1 mmanya

(2) moto ikuku: 11KW (Shanghai Lichao) 1 set

(3) Igbe gia na-atụgharị: elu helical gear reducer (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 set

(5) Akwado igbe gia: 1 set nke ike

(6) Mbelata ọsọ ọsọ: eze siri ike 1 set nke ike

(7) Onye na-agbagharị ọsọ na-agbagharị agbagharị: 1 nke ike

(8) ọdụ ụgbọ mmiri hydraulic na-ebupụ

7.Auto ikuku aro puller

8.Drive ngalaba

8.1 Isi moto, eriri nnyefe na-eji eriri synchronous

8.2 Mgbakwụnye, rewinding na unwinding moto: Drive belt nakweere arc gear, yinye na synchronous belt nnyefe

8.3 Igbe ihe eji akwọ ụgbọ ala: Akara mmanụ na-emikpu mmanụ, Usoro nnyefe ihe eji eme ihe.

9.Control Unit

Kabinet eletriki nọọrọ onwe ya, njikwa etiti etiti, ebe ihe mejupụtara ya nwere ọrụ kabinet njikwa etiti. Sistemụ akpaaka igwe na-eji ngwaọrụ PLC (hollsys) nwere ikike nhazi dị elu, yana akara mkparịta ụka igwe mmadụ na-eji nkwukọrịta netwọkụ n'etiti interface. PLC, ngalaba extrusion, mkparịta ụka igwe mmadụ n'etiti sistemu ịnya ụgbọ ala yana mebere sistemụ njikwa akpaka agbakwunyere. N'ihi na ihe ọ bụla parameters nwere ike ịtọ, na akpaka ngụkọta oge, ebe nchekwa, nchọpụta, mkpu, wdg nwere ike erughị ala nke visual ngosi ngwaọrụ, ọsọ, mkpuchi ọkpụrụkpụ, ọsọ na dị iche iche na-arụ ọrụ ọnọdụ.

10. ndị ọzọ

11.1 Ntuziaka Roller: ike anodization nke aluminum alloy akwụkwọ mpịakọta, usoro mmegharị

11.2 Ngwa voltaji dị ala maka France Schneider, omron Japan, wdg.

11.akụkụ ika

11.1 PLC (Beijing Hollysys)

11.2 ihuenyo mmetụ (TAIWAN)

Ihe ntụgharị ugboro 11.3: Japan Yaskawa

11.4 Isi moto: SHANGHAI

11.5 obere esemokwu cylinder (Japan SMC)

11.6 AC kọntaktị (Schneider)

11.7 bọtịnụ (Schneider)

11. Static igwekota (Taiwan)

11.9 cylinder mgbali na-achịkwa valvụ (Taiwan)

11.10 Magnetik mgbanwe valvụ (Taiwan)

11.11 ziri ezi nrụgide na-achịkwa valvụ (SMC)

12.Customer onwe na-enye akụrụngwa

12.1 Oghere akụrụngwa na ntọala

12.2 akụrụngwa ọkọnọ maka igwe eletriki kabinet

12.3 Mmiri na-enye akụrụngwa n'ime na n'ọnụ ụzọ ámá (onye na-azụta ihe na-akwadebe mmiri oyi)

12.4 Gas na-enye igwe etinyere na stomatal

12.5 Ọkụ na-ekpochapụ na fan

12.6 Na-anakọta, na-ebu na ibutu ihe ndabere nke ngwá ọrụ emechara

12.7 akụrụngwa ndị ọzọ edepụtaghị na nkwekọrịta

13. Ndepụta akụrụngwa:

| Mba. | Aha | Nkọwa. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Onye na-ahụ maka okpomọkụ | Omron |

| 3 | Micro-achịkwa valvụ | 4V210-08 |

| 4 | Micro-achịkwa valvụ | 4V310-10 |

| 5 | mgba ọkụ nso | 1750 |

| 6 | Mgbasa ozi siri ike | 150A和75A |

| 7 | njem mgbanwe | 8108 |

| 10 | kpo oku unit | ϕ90*150mm,700W |

| 11 | kpo oku unit | ϕ350*100mm, 1.7KW |

| 12 | kpo oku unit | 242*218mm, 1.7KW |

| 13 | kpo oku unit | 218*218mm, 1KW |

| 14 | kpo oku unit | 218*120mm,800W |

| 15 | bọtịnụ Schneider | ZB2BWM51C/41C/31C |

| 16 | ọkpa ikuku | |

| 17 | teepu okpomọkụ dị elu | 50mm*33m |

| 18 | telflon teepu | |

| 19 | Corona mkpuchi rola | 200 * 1300mm |

| 20 | Mpempe ọla kọpa | |

| 21 | nzacha ihuenyo | |

| 22 | Kesaa slits | 150*80*2.5 |

| 23 | pneumatic njikọ | |

| 24 | egbe ikuku | |

| 25 | nkwonkwo mmiri | 80A和40A |

| 27 | kposara na ndị ọzọ | |

| 28 | ịdọrọ yinye | |

| 29 | igbe ngwá ọrụ |

Isi akụkụ na foto:

Unwinder (Auto splicer) → web guiding → Corona treater → Extrusion and compounding part Edge Trimming → Rewinding